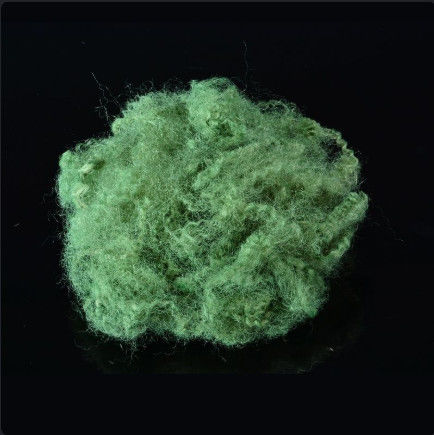

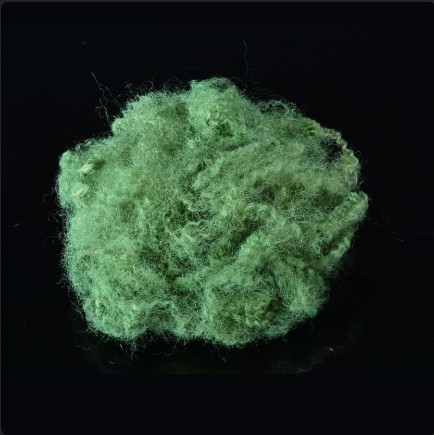

Jade Green Dope Dyed Fiber For Clothing Industry

11.11detx*64mm Jade Green Full-Dull Dumbbell Dope Dyed Fibers Energy Consumption

1. Introduce

Dumbbell polyester staple fiber is a kind of profiled fiber whose cross section is similar to dumbbell shape produced by using a specially designed spinneret and processing technology.

Dope dyed fiber are “naturally beautiful”, without the need to be dyed afterwards, not only reducing the steps in printing and dyeing, saving energy, and reducing emission, but also delivering bright-colored textiles, uniform in color, endurable and not easy to fade in color during the consumption and use of its fiber products. Currently, compliance with environmental protection means following the trend, progressing with times.

Dope dyed refer to the colored fibers obtained via spinning process by adding coloring pigment in spinning solution ormelt. As known as non-dyed fibers or pro-spinning dyed fibers. To process dope dyed fibers to textile products can omit the coloring procedure, with prominent features of reducing large amount of wastewater and carbon dioxide emission, save energy consumption and protecting environment. In this regard, the outstanding problems confronted by traditional printing and dyeing industry, such as high energy consumption, high water consumption and high COD emission, can be effectively solved from the source. Affectively solved form the source. According to statistics, compared with conventional polyester fibers, the dope dyed can save 89% of water consumption, 63% of energy consumption, 63% of chemical produce usage. 62% carbon dioxide emission and 67% COD emission.

Under the background of increasingly stringent regulations on environment protection and increasingly interiorized concepts of green development and green consumption, dope dyed fibers have been developed rapidly in recent year.

2. Specifications

| Name |

Full-Dull Dumbbe11 Dope Dyed Fibers |

| Material |

100% polyester |

| Denier |

11.11/ 13.33Dtex |

| Length |

51/ 64MM |

| Color |

Many Colors such as Jade Green, Royal blue, Ocher, Yellow, Bronze |

| Feature |

Dumbbell fiber has excellent flash and refraction properties because of its special cross section shape. It is also breathable, fluffy, crisp, smooth and has strong sense as wool. |

3. Application

Dumbbell fiber usually blend with chemical fiber and natural fiber. It is a good imitation of rabbit hair fiber. If it is made into cationic easy-dyeing effect will be better and its luster will be more brighter. It is widely applied to coat, sweaters, casual wear and fur clothing,

4. More pictures

5.Why dope-dyed fibres?

Wet processing, a common step used in the textiles industry, has the potential to cause a significant impact on the environment and on human health. This is because large amounts of chemicals and dyes are used in wet processing, resulting in effluents with a complex chemical composition. The cellulosic textiles industry consumes a large quantity of water in wet processing operations like desizing, scouring, mercerising, bleaching and dyeing during conversion of fibre to fabric.

The last decade has seen growing concern about environmental issues which have increased manifold because of increasing industrial pollution, waste problems and the effects of global warming. In this context, dope-dyed viscose is one of the solutions in reducing environmental pollution and wastewater discharges in the textiles industry.

6.Our Infrastructure

Since the incorporation of our firm, we have constructed an advance infrastructure base at our premises. To have flawless control over business operations, we have partitioned this unit into several departments such as manufacturing department, quality department, warehousing department, packing department, R&D and logistics department. These departments are managed by our extremely diligent professionals.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!